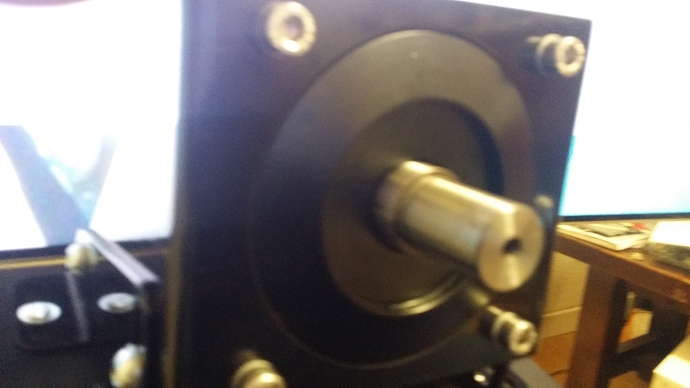

omg, there is a lot of oil or grease. Should i use Ethanol or 99.9% alcohol? I do have both of them.

Either one would work fine.

Hi Martin,

Make sure that the E-stop is not pushed in. The firmware programmed at the factory has an issue and requires the e-stop to be not pushed in and the device fully started up for the “go to firmware update mode” command to work.

That was it - thanks. Got also the info for that from german forum

Mine is not slipping so far (indycar18 on belle isle well into clipping would slip).

I recommend a D-Limonene cleaner - works as good if not better, non toxic.

Just an FYI for anyone interested. The XERO QRs are also being sold at Bodnar, perhaps at a slightly lower price.

http://www.leobodnar.com/shop/index.php?main_page=index&cPath=101

You can also use paint thinner or mineral spirits. I don’t have an SC2 yet, so I’m not sure if the shaft is painted. So some of these ‘solvents’ would be harder on paint than others. Alcohol would be my last choice to remove grease.

PS… not affiliated in any way with Bodnar.

I have assembled SQR on multiple prototype SC2’s in our labs and it has been always sufficient step just to wipe the grease from shaft and cone clamp element bore with a paper/napkin. No solvents necessary. Actually I prefer paper only cleaning to avoid solvent ending up in ball bearing.

Then tighten the four black screws as tight you can with manual hand tools (max tightening torq is 17 Nm, which is more than an average person can produce with a tool). 5 Nm tightening torq should be well enough (5 Nm is a common tightening torq for screws). If it still slips, just tigthen more.

I hope this helps!

PS fun fact, the cone clamp element inside SQR can hold shaft without slipping up to 290 Nm

Yes when I read the spec sheet I was surprised to see the holding torque!

This is an excellent update to see, thank you Tero!

Knowing for sure that GD is committed to providing early owners with a production solution on a reasonable timeline goes a long way. Thank you again!

Actually Bodnar would’ve been more expensive than importing to the UK for me, plus you don’t get the hub adaptor that HRS makes for the Simucube AFAIK.

Simon

Don’t forget to check out the hubs that Brett HRS does!

The AKM version should fit the SC2 perfectly.

HRS may not be the least expensive, but it will be the nicest that you can get.

Back when I was really busy with the Argon and Ionix1 builds I tried to talk Brett into making something simple, similar to another manufacturer.

I will never forget his response when he did not want to do it. And I respect him for that.

He said Joe "I am an innovator not an imitator "

Hello guys. After short difficulties with fw-flash my SC2 Pro is working and I have driven the first laps in Iracing. Is it possible to open a new thread for:

- explaining the filters and settings in truedrive

- another one with recommended filtersettings from GD they would apply for theirselve or use when presenting SC in front of customers

For example yesterday I tested the static torque redcutions filter. I felt that with slewrate limit off it doesn´t work. But with recommended slewrate from Beano “1” and 30-40% it feels not realisitic because it seems that the reduction is a slow curve and that feels like the clamp is not mounted fix to the shaft ;-). Just my first feeling.

Overall first impressions are really positive. Good Job GD!

That’s what I meant Joe, it was cheaper for me to get the HRS direct from Brett than buying in the UK from Bodnar, plus he sent me his beautifully machined SC2 hub

The adapter has originally been designed for two use cases:

- mount a 70mm bolt pattern from the back side

- mount an alternative 70mm QR to the SC2 shaft clamp

The M5 threaded holes are no through holes and have a thread depth of 5mm. This means that it doesn’t solve the screw length issue in its current form.

The next batch, which is already in production, is changed to M5 through hole threads to add this third use-case and solve the screw length issue.

The height of my adapter is 10mm, which means that there is enough tolerance for standard screw lengths to mount a steering wheel + button plate + adapter from the front side.

The round shape instead of star shape is certainly not an issue due to the small diameter of 81mm.

Ahhhhhh ok. I read hub adapter and I thought you were talking about a plate.

Did you get the new 3pc hub? I have not seen one in person yet. The older design Mige and AKM 1pc hubs were beautiful!!

very little grease i found there…do i have to clean it up ? Or must i unmount further ?

thanks

Just clean most of the grease and assembly back.

We are of course all very sorry about these inconvenient issues.