I just bought very cheap SimuCube 1 with the same problem, the servo is Kollmorgen AKM53G and encoder Hengstler AD58 / 1222, 12bit+22bit=34bit so more then 32bit unfortunately . Looks like only 20bit I can use so only 1 mil instead 4.2 mil cpr. Still no way to fix it somehow?

still no way to fix, unfortunately. Adding more bits for reading in the IONI would slow down the operation of the servo drive, and also using more than 32 bits on a 32bit processor that does not have too much extra performance, would cause troubles.

Thank you Mika, where can I buy Biss-C 22bit? Liza from Mige company China? Hard to find in EU.

I have it in the USA.

Lisa should be able to help you. Be sure to order it with the cable!

Liza from Mige would be a good guess. But I do not know if such encoder is physically compatible with AKM motors.

You are right! It doesn’t fit directly on the AKM.

You have to make a tapered shaft as well to fit the Mige Encoder.

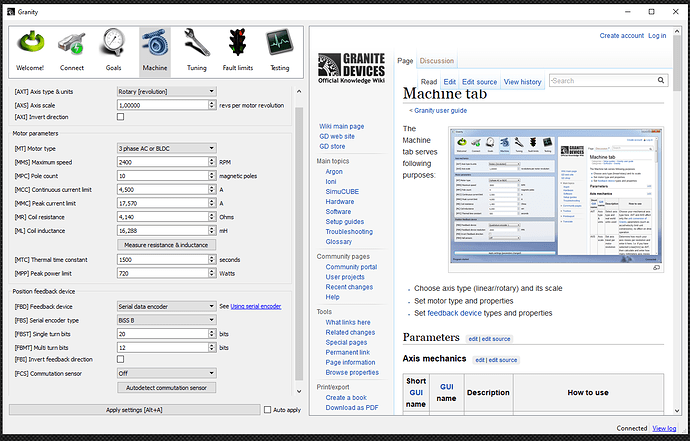

Yeah, I know. Thanks. I have to say that, after few hours testing AKM53G, this is amazing servo for me, the feeling of the car is… very, very realistic and more analog then Mige somehow, this is G version maybe that’s why? I don’t know. I was only worry about the cogging, I remember Tommi’s warning, but cogging compensation works great in Granity, this problem gone. Are my settings correct? What you think? I have SDR480/720W. Looks like MCC is too low…

Mirek: I will visit my laptop later tonight again and update you on mcc/MMC

Yes, AKM in my humble opinion is very good servos, I prefer K over G due to even lower cogging, but they both can be tuned to very good levels. The fact that they have bigger pole-count most likely contributes to the tunability.

My servo of choice has been an AKM65L, married that to an SC2 controller, with special fw, as I am running reliability tests at high current-levels for GD, it has been probably 2 years at extreme levels, and controller is still smiling.

I get back to you on settings for that monster though.

I like my 53G very much as well, but would rather choose a smaller Servo with less inertia. Like AKM52G or so (6.2 kgcm^2 instead of 9.1 kgcm^2)

Right now I rarely use 50% of the power / torque, which is why a 52G should be sufficient as well. It is arroung 2/3 of the torque.

*sure, the K version has less cogging, due to lower Nm/A ratio. But therefore you need almost double the current for the same torque

Or even better a Servo like the Simucube Ultimate -very thin dimensions to reduce inertia even more.

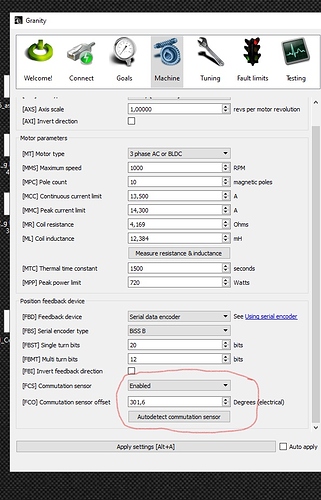

My settings are:

MMS 1000 (Datasheet 1000@230V)

MR 3.97 (Datasheet 3.75)

ML 21.3 (Datasheet 21.3)

MTC 1680 (Datasheet 1680)

MCC 14 (my personal setting - close to MMC)

MMC 14.3 (Datasheet 14.3)

Some people actually like the natural mechanical damping the higher inertia servos provide, I am one of them. My akm65 servo has a shaft-diameter of 32mm, vs the 24mm of the akm53/54, for example, just to give you an idea.

Having used everything from Lenze, various small and large Miges, quite a variety of other servos in OSW days, 5 or 6 different akm servos, Podium DD2, and SC2 Pro and Ultimate, I have a fair understanding of what to expect from each servo at whatever setting.

Out of all of those, my personal preference is one with higher mechanical damping, which can be emulated to a degree on the Ultimate via slew-rate and electronic damping, but I prefer the natural damping over electronic anyway.

Even in my old Lenze days, I added a 1kg ballast to the special hub I designed back then, to provide the damping I was after. So it’s all quite personal, some like the noisy/spiky ffb that low/no filters provide, others like higher damping and smoother signal, but the beauty of these systems are that we all can find something we like

I have written here exclusively about my personal taste and preferences. It is obvious here that this does not have to agree with everyone.

You have written it perfectly and I have nothing to add.

It’s a great time in sim-racing history. I remember a time that we all dreamed about DD wheels, then had nightmares about the Bodnar SS2 high-end wheel everyone wanted, but very few could afford….

Long road we have come, just glad we have so many options now

Beano, I wish to try your AKM65 but I could probably go only straight… hehe. Simucube Fan, we have the same servo but totally different MMC/MCC settings

Ha Mirek, I usually run it between 22-35NM torque, that’s solid enough for me. But the high ceiling means not clipping in iRacing ever  That’s a good reason for using the large servo with high-torque capability.

That’s a good reason for using the large servo with high-torque capability.

OK, more thoughts about my new baby… SC1+AKM53G. I think I know why I bought this wheel so cheap (around 650 euro). If I changed MCC higher then 4,5 A I had the motor fault, under voltage, initialisation fault, but even with MCC 4,5 A I couldn’t set the wheel center position to permanent memory as well so even 4,5 A was too high, I had error during this process. Thanks God it was easy to fix, the problem was in drive faults limits, [FUV] was set to 30 DC volts, too low, it should be 43 DC volts (for 48V). MMC was also incorrect, almost 18 A, should be 14,3 A. Now all is fine. No faults anymore. I can set the wheel center position to permanent memory with no problem. My MMC/MCC is now 14,3/13,5 A. Thank you SimuCube Fan for sharing you settings and info about the data sheet of AKM53G. Looks like the knowledge is very important in simracing and rally

This is the setting for absolute encoder mode where the wheel use absolute encoder information to get the relationship between motor phases with regards to encoder, thus phase search routine is not required. You can do exactly the same enabling/disabling in the Motor Configuration Wizard in Simucube Configuration Tool.

Ah… OK, thank you Mika

Mika, how to set [MMS] max speed correct? In data sheet is 1000rpm/230V but we have 48V in SC1? Is this setting important? Maybe 200rpm should be or so?