Hi, will there be a way to extend the new SQR, or should i extend every single steering wheel?

Consult our resellers for extension options. One way this could be accomplished, is to remove SQR front plate (wedge) and add a shaft with correct flange and holes to reattach the part. Another way is to remove the SQR completely and mount just the wedge part to suitable part on the end of the extension that would be attached to the motor end via similar means as any extensions.

The servo motor bearings in these industrial servo motors are not really meant for shaft extensions without a separate load carrying bearing, so only short extensions are recommended.

What is the mounting pattern that the wedge is connected to the Simucube end of the shaft with? Is it a standard 50mm or 70mm pattern?

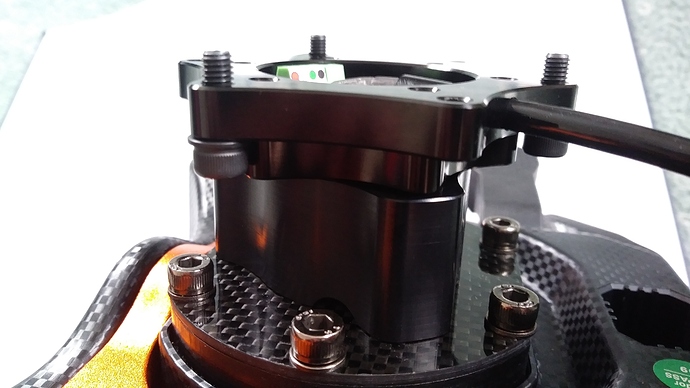

It’s a 50 mm pattern but you will also receive a 70mm adapter plate:

https://racewerk.com/blogs/news/first-impressions-with-the-simucube-2

Be careful here, the wedge that bolts onto the wheel-hub May look like 50.8mm, it is not…it is a custom hole-spacing, unequal distance at that…

Wait, what?

Your sentence seems to imply that many of us are going to be majorly disappointed next week when we received our packages.

If you remove the wedge-part from the actual hub on the servo (servo-side wedge, not wheel-side), that is a custom bolt-spacing.

So got guys wanting to add an extension between the servo and the QR, you need to take that into consideration. Adding and extension between the QR and the wheel-rim though, no worries, an adapter is included.

That’s why I was careful in my reply above, stipulating which wedge I was talking about

Thank you for that additional information Phillip. Very good to know

Cheers Bud, you’re welcome

This is my first DD, so pls sorry for all my questions.

Unfortunately my new rig is not able to manage more distance between the screens and wheel base.

I think it’s needed a spacer around 150mm, because otherwise the screens are to near for my eyes. Do you think 150mm is too much for the servo motor?

Also other solutions or ideas are welcome

Most people like to have screens as close as possible, and the popular use of extension is to allow mounting the displays between the wheelbase and the rim. 150mm does not sound too much, although care should be taken for not to use the wheel rim as a handle bar when getting in/out of the rig.

Mika could you please confirm that am 70mm wheel can used with the new Simucube 2 out of the box.

My understanding is that an adapter i required.

Is an adapter in every delivery included?

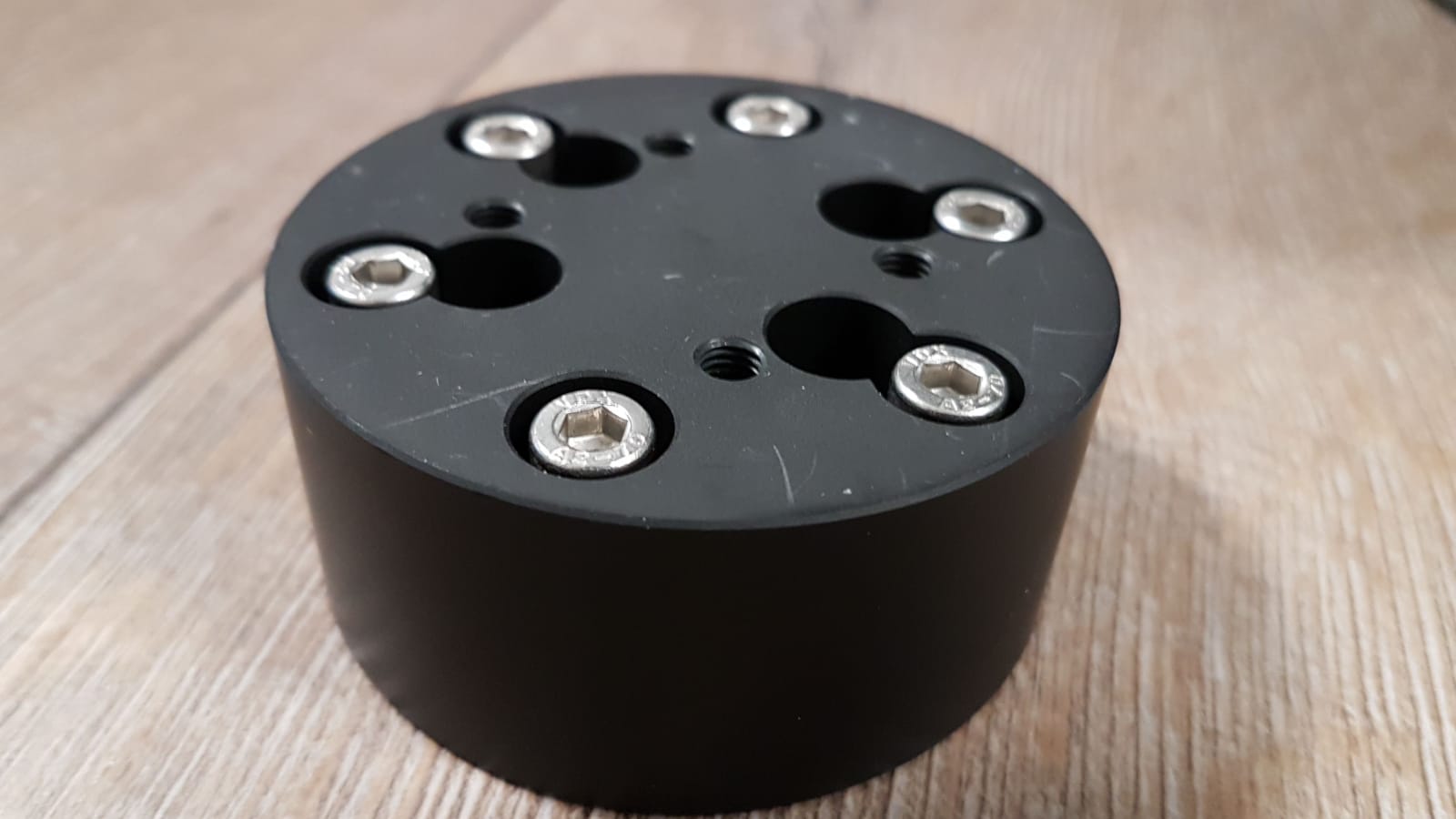

Yes, the shipment includes 1pcs wheel side SQR, 1pcs 30mm spacer, and 1pcs 70mm adapter that supports bolt through the wheel from front -mounting. Mounting to 70mm from back side is not supported, but I do believe that Martin Ascher has a solution available.

Mika, I thought I would post this here as I don’t want to derail the main thread any further.

Do you think this arrangement will be sufficient if I were to use blue thread lock as you had suggested?

As you can see, I will have 3 bolts that will extend 4.5mm into the 70mm adapter. I am unable to use all 6 holes as the hub does not have enough clearance to allow them all to pass through.

Thanks for your time

I believe that should be enough.

I dont get it. How am I supposed to mount the QR onto my simsteering wheels?! This wheelside part makes no sense. If it only had 3 holes in a 50mm pattern for cylinderhead screws…

There is that middle part… way too long. If it were a few mm it would work but not as it is.

back mounting to 70mm bolt pattern is not supported. If you have 50.8 mm pattern, then use the 70mm adapter, it should have required holes.

Simsteering wheels are all 50mm.

Cant use another distance than it was because Z1 display etc.

The other issue are the shiftercables from simsteering. So I cant remove that extention and mount the QR directly to the wheel.

Looks like not a single betatester had a simsteering wheel…

Well thats kind of a bad start…

Edit: This is not intended for a Mika, but for Community!

Like I said to you already yesterday, it is fine. I have run 3x 5mm bolts on a 38NM servo for almost 2 years.

Wishing sometimes people will trust when those with actual experience on these matters will trust the feedback. If you want, add a bit of blue Locktite on the threads. It won’t go anywhere after that.

It seems people are thinking that the bolts will carry a hell of a lot of force in the shear/rotational direction…they don’t. It is about clamping, and I have for a long time use 3 bolts in a 5mm p,ate at torque levels none if you will ever see.

It is fine