Hi, I have a question regarding Argon regarding Oscillation at idle .

My hardware configuration:

-ARGON

-CONTROL TECHNIQUES 075U2D305BAEBA075140

-2110

-18M long cable

Encoder: heidenhein eqn 1325 1vpp sin/cos and endat01

Problems arise when:

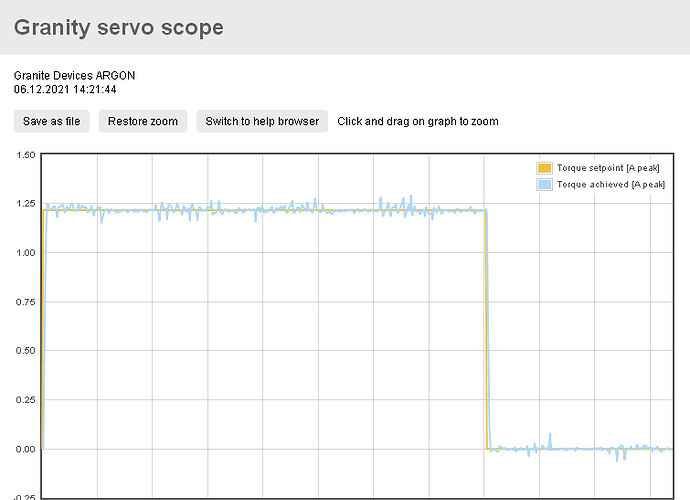

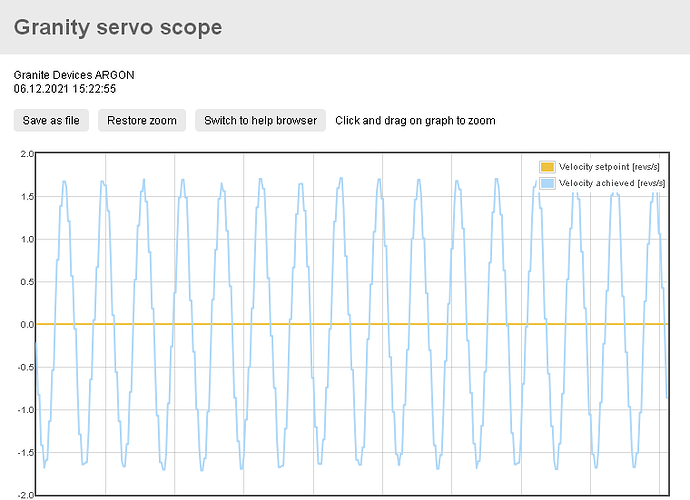

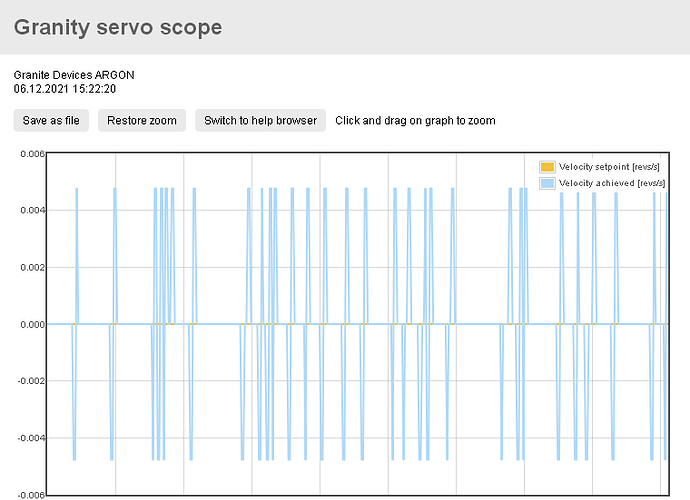

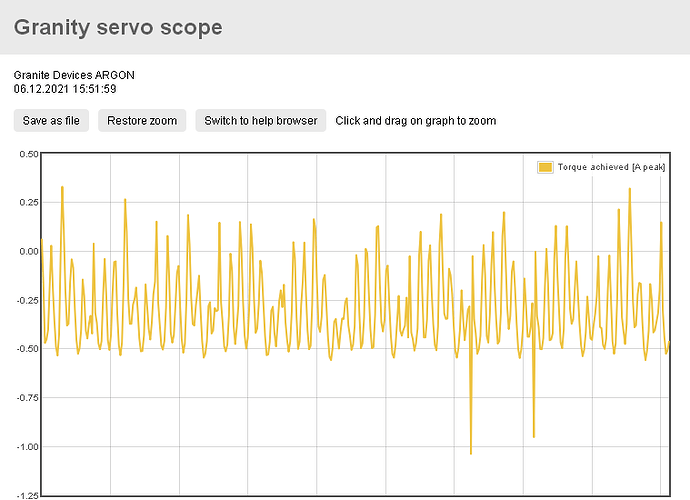

After torque mode setting when i change to velocity mode the motor starts vibrating without a set point.

if i input a set point the motor starts to rotate correctly but without the vibrations.

How it behaves:

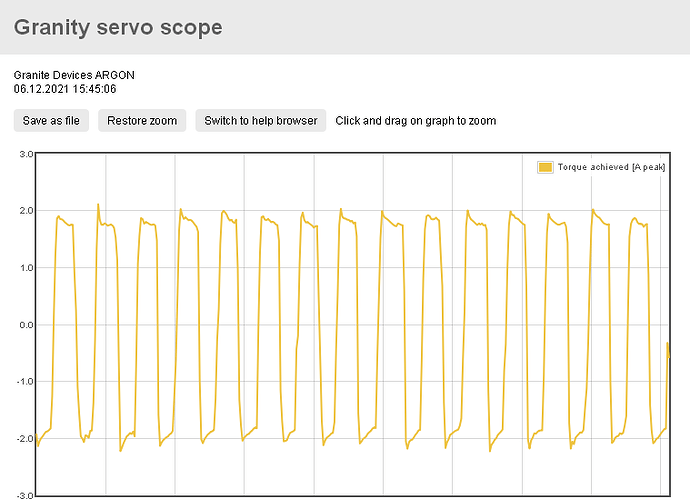

-oscillation without load.

If is set [KVP] to 5 it stops oscillating.

How I would expect it to behave:

Stay still

I have attached following files:

-(consider adding saved Granity configuration file .drc)

-(screenshots)

I also would like to share that (additional info).

the ferrite core on the servo cables is getting warm.

encoder cable: stuttgart olflex servo fd 798 4x2 twisted pairs shielded

connectors:m23

servo cable: 4x2mm3 plus 2x1mm3 independently shielded orange servo cable

i have resistance and inductance values from the motor manufacturer

i have 2 similar motors with the same encoder/ pole count and i tested them both and appear the same symptoms.

I have installed 120 ohm termination resistors on the (A+ A- )(B+ B-)

ferrite installed on 3 servo phase cables and on power input

mains power filter siemens 3 phase and neutral 65a

i have double checked grounding on everything.

Drive chassis is grounded

All servo cables are grounded on the ground conductor and both shields

Encoder cable shield is grounded on the connector

I have checked insulation resistance on the motor and servo cable with everything disconnected. Multimeter 200Mohm. Checks:

Phase to phase

Phase to GND

Phase to shield

Motor case to motor phase

Motor brake to phase

all good

Position feedback (raw) is rock stable when the drive is not enabled.

Thank you for your time,

Dimitris