Hi everyone,

I am going to build SimuCUBE based OSW kit (with Ioni Pro) and currently I am thinking about servomotor.

I know that MiGE 130ST-M10010 (20Nm) is proven by many simracers, but I don´t know how quick it reacts in some situations (like miniature corrections due to oversteer etc.).

Recently one real racer said, that slow responsiveness is still some kind of problem in simracing, so I am curious if similar motor with higher speed and less inertia should be a better choice?

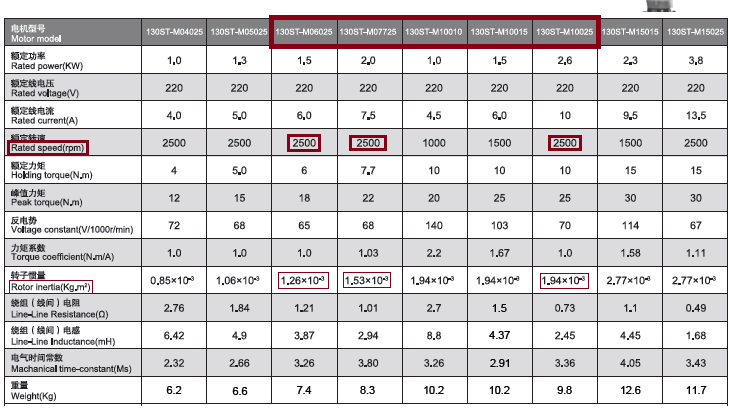

(I am thinking about 130ST-M06025 / 130ST-M07725 / 130ST-M10025).

Does anybody have experience with it? And can I feel any difference at all?

Thanks for your time!

Tomas

I suppose that real driver has never tried any kind of DD wheel.

Motor’s inertia is pretty much insignificant compared to wheel’s inertia.

Smaller motors get hot faster though and if i remember correctly wheel speed is software capped

Wheel speed is capped by voltage. The motors are rated for 220 V voltage and the indicated values in the datasheet represent the RPM the motor will run at that voltage.

Thanks for all answers! So I suppose that the best choice will be ‘small Mige’ ?..

20nm Mige (130ST-M10010) will be your best choice, chances are you will anyway add some filtering to ‘slow’ the servo response down a bit, as it is a pretty active servo, capable of replaying most/all the setpoint signal content coming from iRacing.

Like stated above, that real-life racer is either talking porkies, or he has never tried a proper dd wheel.

Cheers,

Beano

Sorry if I say nonsense. The “big” MiGE 130ST-M15015 (30Nm) has higher speed (1500 rpm), although it is true that it also has more inertia, but I don’t know if for which Tomas_Borl is looking for would be more suitable.

Perhaps its greater speed does not compensate the one that has greater inertia. I have not tried a “small” MiGE, but I have an “big” MiGE and I think it has a very fast response.

Lols. There are a few things you need to learn about this application and suitable servos before you say nonsense. There are more factors then just speed and torque at play here, there are also nm/a ratio, winding resistance etc.

I have given my advice based on 5 years of extensive dd wheel experience, do as you see fit, no skin of my back.

The Mige M10010 is by far the best in terms of efficiency, for this application. It has a 2.2nm/a ratio, allowing it to do 20nm from just a 360w psu. Plus, you only need an Ioni Pro to get the max 20nm from it, and actually, it is so efficient, I can use the spare capacity on the Ioni Pro to overclock it to the same level as the M15015

The M15015 you sing the praises of, has a 1.58nm/a ratio, but needs an Ioni Pro HC and a 560W psu to get it to 27.9nm, as it is power-hungry and cannot get to 30NM from the 25A POS limit of the Ioni Pro HC.

Another thing you may want to consider, the rated speed of the M10010 places it in the sweet spot for max rpm desired for dd wheels too. Yes, before you ask, I have also owned and tested the M15015, and probably 30 other servos. It is a good servo, but overall dd wheel cost will be quite a bit higher for Ioni pro hc and bigger psu, for not much more torque, vs the small Mige.

Plus, it has a lot of extra inertia when compared to the small Mige. Good if you like the mechanically dampened feel if the larger servo, not so good if what you’re after is maximum speed of response…and in this case, the significantly lower inertia of the small Mige makes it much faster than the large Mige.

Sure enough, I said nonsense.

Beano, I already know that you are a DD guru and, I have learned everything I could from your articles.

Thanks so much for the explanation.

HA, all good, Carlos, no dramas

It is anyway intersting to get feedback from the community on their preferences, where ffb are concerned, we are all different.

As long as you are happy with what you have, nothing else matters!

Have fun, thats important.

Cheers,

Beano

After reading the posts here I am wishing I had done more research before purchasing! I bought a medium MiGE (ST130-AM10015) thinking this would be a compromise between the small and large MiGE. I purchased the Meanwell SDR-480-48 and IONI Pro HC board and SC1 controller complete and now I am searching for help with the configuration drc file. I would appreciate any advise I can get as this is all new to me and I can see that there are experts here who may help. Thanks in advance.

Hi, do you know which encoder you have fitted?

Hi, yes its the BISS-C encoder 22bit although I haven’t taken the cover off to get the model number.

There are only a few basic things to change form an existing small Mige m10010 BiSS-c drc file then. If you can find a BiSS-c 22-bit drc, then upload that, and use the ‘measure resistance/inductance’ button in Granity, that should set you up nicely.

After that, just push the ‘save to drive button’ on the first tab and restart, you should be good to go. If you battle, I can also give you the factory resistance/inductance values so you can set them manually. Get that up and running first, we can fine tune MMC/MCC after, the base small Mige settings for them should at least get you up and running.

For the record, the general major deviations between different servos will be;

Magnetic Pole Count, not in your case though, it remains at 8

Motor RPM, you need to adjust this based on your motor specs

Coil Resistance and Inductance, either let the software measure it, or adjust manually based on your motor specifications

Encoder settings , adjust based on your servo specifications

Motor current limits, MMC and MCC, adjust based on your servo specifications

PSU selection, but the SDR-480-48 will be good enough for your application

Cheers,

Beano

That sounds great. Thank you so much for your help! Ill let you know how I get on with it.

Ok, here are some settings to change from M10010 drc file to M/A10015 settings:

Change 1,000rpm to 1,500rpm

Coil Resistance 2.70 ohm to 1.5 ohm

Coil Inductance 8.8mH to 4.4mH

MMC ~12.8 to 17.0

MCC ~12.0 -> can leave it the same

As said, if you use the small Mige BiSS-c file, then you don’t need to change anything other than the above. This servo should give you close to 25NM max torque, it will force the psu up to around 542W, but the SDR can handle short spikes like that, if it trips on torque, reduce MMC to ~14-15A POS.

Let me know how it goes.

Cheers,

Beano

Wow you’re a legend! Thank you so much for this info. I’m just waiting for my box to arrive from China then ill mount the electronics and start the configuration. Will keep you informed. Thanks again for all your help.

Cheers Mate, you’re welcome

HI Beano, I wrote a long message here IONI Drive Config Files for MiGE 130ST-AM10015 (medium MiGE) and would really appreciate any assistance either you or others can offer.