Here’s some photos and information of my most ambitious and time consuming project, a CNC mill project I have been working on to be used at our space club Castor’s club room, available for club’s student member use. Most of the design and work has been done by me on my free time, with few exceptions:

- Machining of main Z-axis parts: Department of Manufacturing and Automation, Tampere University of Technology

- Thanks to Juha Koljonen for arranging the machining of Z-axis parts and some other arrangements

- Thanks to members of Castor club for their patience with the slow progress at times

Other shout-outs:

- Thanks to the best company in the world, Granite Devices, for motor controllers

- Thanks to Granite Devices and DamenCNC for the TeknoMotor spindle motor

- Thanks to Omron for the VFD

Main components and specifications:

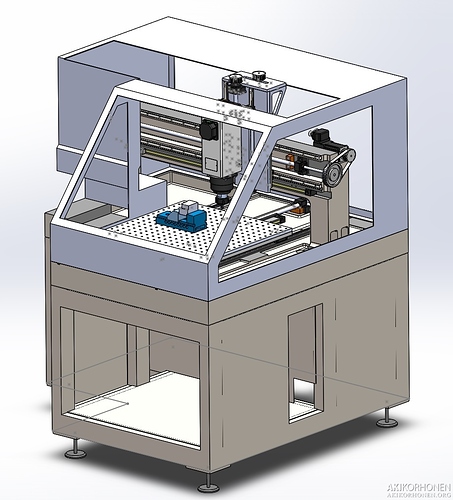

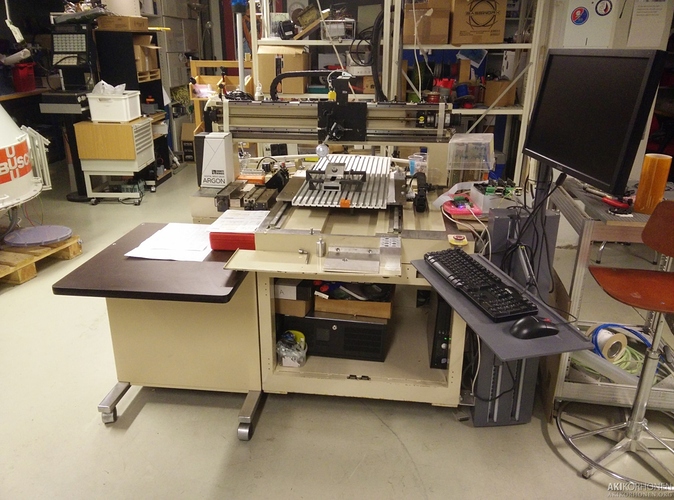

- Frame: Fuji Digitizer and Feeder Calibration machine DT-651E (120cm width, 116cm depth, overall height around 140cm)

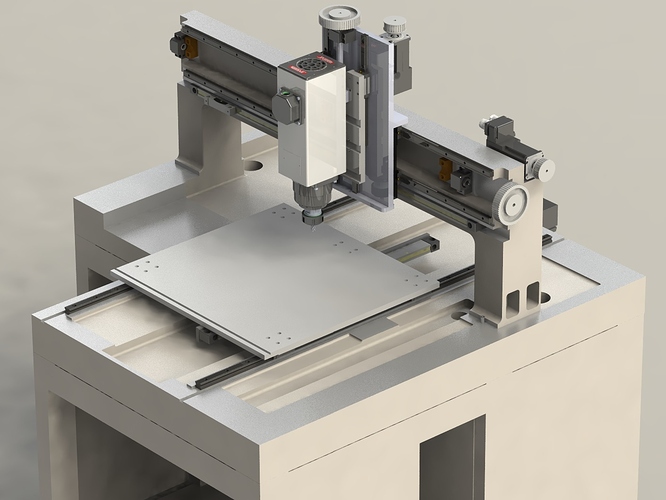

- X-axis: 810mm max. travel // zero backslash NSK ballscrew (16mm D / 5mm lead) // THK linear rails

- Y-axis: 550mm max. travel // zero backslash NSK ballscrew (16mm D / 5mm lead) // THK linear rails

- Z-axis: custom design with 180mm max. travel // Bosch Rexroth STAR 1502-0-1065 (16mm D / 5mm lead) // THK linear rails

- A-axis: TBD

- X-axis motor: Pacific Scientific (Kollmorgen) Powermax II P22NRXA-LDS-NS-02 stepper (later Yaskawa SGMP-04V314T 400W AC-servo + Miki Pulley SFC-030WD coupler)

- Y-axis motor: Pacific Scientific (Kollmorgen) Powermax II P22NRXA-LDS-NS-02 stepper (later Yaskawa SGMP-04V314T 400W AC-servo + Miki Pulley SFC-030WD coupler)

- Z-axis motor: Tamagawa 4073N27E31 300W AC-servo with lock

- A-axis: TBD

- X-axis linear encoder: Mitutoyo AT111-800F (539-215-10)

- Y-axis linear encoder: Mitutoyo AT111-500F (06AAJ425)

- Z-axis linear encoder: TBD

- X/Y/Z/A-axis motor control: Granite Devices Ionicube4x + 4x Granite Devices IONI Pro Servo controller

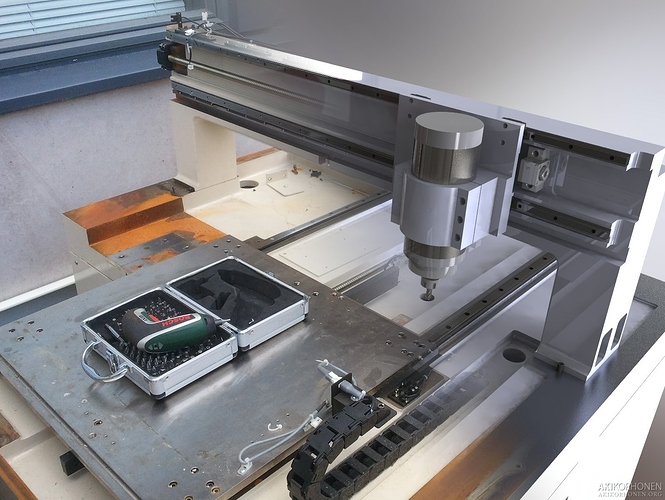

- Spindle motor: TeknoMotor ElectroSpindle C51/60-A-DB-P-ER32-HY-3.3KW-18000-24000RPM // 3.3kW with ER32 collet

- Spindle VFD: Omron 3G3MX2-A4030-E 3/4kW

And then to the most interesting part of the build: the only parts acquired new are Granite Devices’ motor controllers, Omron VFD and TeknoMotor spindle motor, EVERYTHING else (including the frame) is salvaged free from various recycling spots and discarded machines around our university.

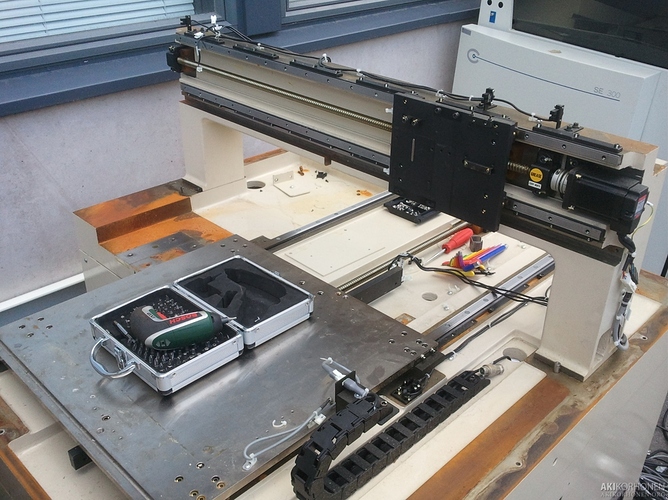

The story of this CNC mill project started one day when I stumbled upon the 700kg Fuji digitizer frame sitting outside one of the university buildings, waiting for the carbage truck to take it to be scrapped. Luckily I happened to find it in time and salvaged everythink interesting of it first and covered the frame to save it from possible rain (it rained a lot the next day, the condition of the frame would have been horrible after that). The Fuji digitizer was a optical measurement device for calibrating SMD component feeders etc. and it has zero backslash versions of NSK’s ballscrews and Mitutoyo’s linear encoders on both X- and Y-axes. The frame is made of cast steel and the whole frame weights in around 700 kg according to the original device manual, so quite a nice frame to start building hopefully a rather accurate and precise CNC machine.

Some surface rust appeared on some of the surfaces that were not covered in protective oil as the machine had to be stored outside for a few weeks before we were able to get it in to our club room that resides underground. The frame looked much better after removing all the rust.

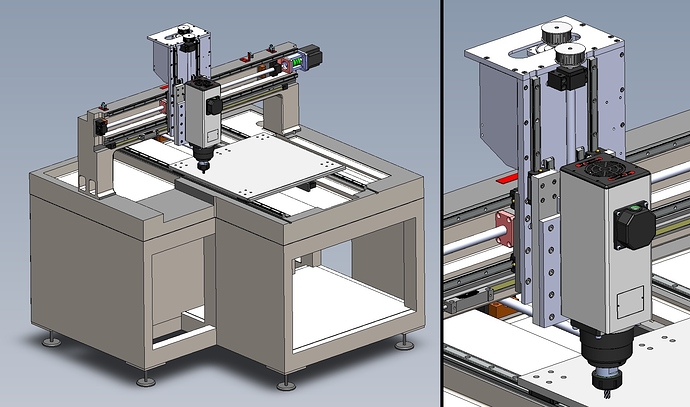

I measured everything possible of the machine and modeled it as precisely as I could so I could design the Z-axis parts. We manually squared up and machined the Z-axis stock parts to size before handing them to be fully machined.

We now have all the main Z-axis parts and in the next post I’ll post some photos of the machined parts and what is the progress with electrics. Can’t wait to get everything together finally and mill out the first chips.