Hi guys,

I have my Simucube Large MiGefor about two years now. Since the last few months however I’ve been experiencing some issues.

Earlier this year I snapped my wheel side USB cable in two while fiddeling with some settings, the wheel went beserk and before I could press the emergency stop the cable was already dead.

I ordered a new bare wire to DIN cable from SRM and after installing I started getting issues with my wheel. Buttons would be activated and random up and downshifts would happen.

Now I know nothing about electronics so the first thing I did was contact Simon from SRM. We’ve been having back and forward chats, he has sent me a brand new conversion under warranty but the problem remained.

Until yesterday I was certain the issue came from the pin connectors inside my Fanatec wheel, heck if the issue didn’t cone back up again I was sure I had fixed it with locking the wheel with the bolt.

So yesterday I started googling again. Well what do you know, dozens of threads with people having the exact same issue, all reffering to EMI.

As I said I know nothing about electronics but if I understand it correctly, an OSW causes a lot of EMI and you need to create some kind of loop to send it back into the ground.

I should add that apart from installing a new coiled USB cable in my Fanatec QR conversion, I also took the time to do some cable management on my rig and stuck a thick rubber mat underneath it to keep my new neighbours happy.

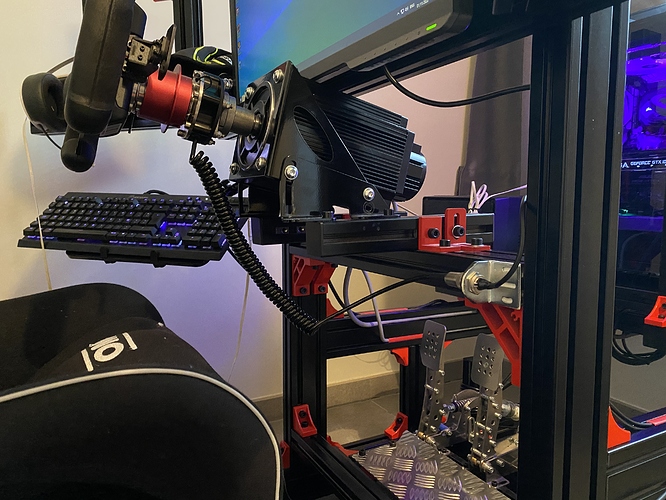

So this is the situation:

Rig

The Rig is an 8020, which I read is good for the EMI loop, but it’s powder coated so I don’t know if it makes any difference. To keep kind of clean i run most of my cables through the grooves.

The motor is a Simucube OSW 30nm with shielded cables.

Attached to it is Simracingmachines Fanatec base side conversion kit. It is grounded internally in the PCB.

On top of that is my Fanatec Formula Carbon. Since the base side QR is grounded and they’re connected bare metal on bare metal I assume there’s no need for a grounding cable here?

My pedals are Heusinkveld Pro’s (which are not grounded and don’t have any issues)

What I think after reading up is that the rig itself has nothing to ground on because of the mat and my controller box sitting on top of a pastic box.

Anyway, i hope this is enough information for Beano

Looking forward to your possible solutions!