Cogging compensation options are available via Granity.

Thank you Mika!

I know, but couldn’t wait to test the Servo in the “car”. I will try to compensate the cogging tomorrow

I tuned out clogging on my 54K completely with sin(12x) -0.07 Amps or something like that.

I believe the formula for which sin/cos value to use is cogsx2/poles. Cogs are how many “notches” you feel when turning the wheel one full revolution. So for the AKM54K (your G motor is probably different) I feel 60 notches while rotating once when the motor is off, and it has 10 poles (should say on spec sheet), so it’s 60x2/10 = 12. Then experiment with con(12x) or sin(12x) adding or subtract small amounts of current until you get close to feeling no notches while you turn the wheel.

Thank you very much roylan!

This went easier than I thought

I have 60 counts and 10 poles as well.

My values are sin(12x) 0.09A

Short test lap with low and high FFB.

The dynamics are really great. I like it very much.

Unfortunately, the cogging is not on the same level as the Mige, but the settings have made it much better. But you can still notice it.

If you put a newbie at the wheel, the Mige will probably feel more natural, since no cogging. The dynamics of the Mige is also not bad at all! But in direct comparison you realize how much more is possible. I hope I can get used to the cogging…

EDIT:

After 1 hour of racing, I got totaly used to the little cogging, since I have to concentrate on so much more thinks, then just this little imperfection of the steering wheel. But still enjoying the higher dynamic.

I’d be interested in what settings youre running in your sim and simucube settings (dampening, inertia, friction etc)

54K Simucube user here - love it, have also managed to effectively tune out all cogging with the compensation settings sin(12x) 0.13A or so iirc. I’ve never detected any ripple (cogging under actuation).

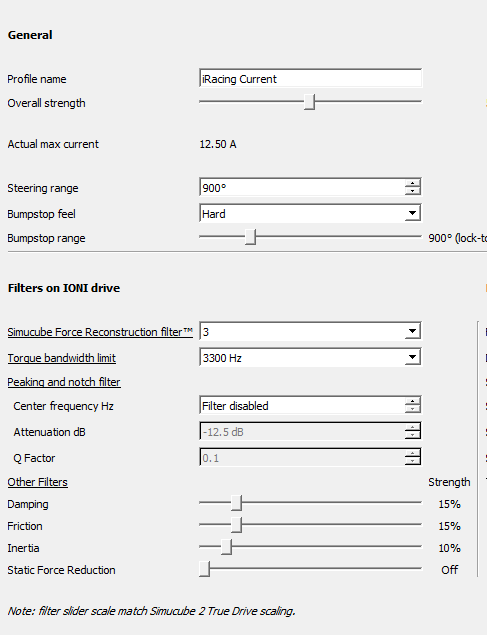

My current settings, which have remained the same now probably for 6months to a year.

Hi Smilen,

Do you find that the torque bandwidth limit has any actual effect on anything? Also do you change your settings for other sims if you play them? Thank you.

Torque bandwidth limit is one of the key settings for me – running it higher/unlimited lets much more high frequency noise in, which I find needs higher recon filters and more damping to tame - it’s pretty useless information as well often feeling like the typical “sandy grainy” sensation.

I’ve run it at 2800 for a couple years, recently turned it up just as an experiment and will be turning it back down in another couple weeks once I have acclimatized.

I’ve noticed a bit of wobble in the encoder, j suspect from the tapered adapter from the coupler to the Biss encoder. I had to sand down my part a bit to fit into the coupler, and I suspect it’s picking up a couple thou of wobble once the set screw is clamped.

I’m guessing the spring steel ears that secure the encoder are supposed to absorb this mostly. I guess I’m wondering if the rotation should be absolutely true, or if some wobble is expected given the couple and adapter to get this to fit?

The rotation should be absolutely true under normal circumstances.

Since this motor is being used for sim racing and not spinning at high speeds the encoder might last.

I personally would try to get it as perfect as possible.

Roger that. I’ll turn another adapter and make sure to check runout on the assembly before final install. Thanks!

Sounds good Ian, let me know how it turns out.

Are you doing the adapters out of metal on a lathe?

Joe,

Yes, manual lathe, aluminum round stock.

I also printed an adapter last night. We will see which works best.