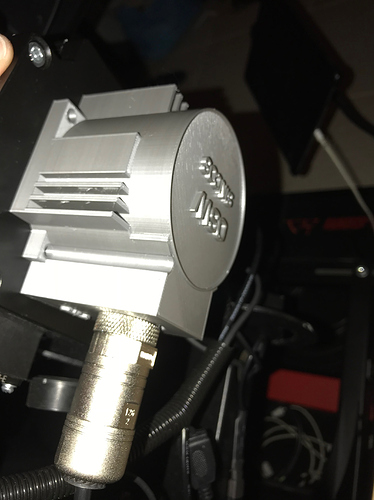

Cover is looking sweet.

nice work and its a goo looking print

I had to extend the “box” a little to allow for easier fitting.

It lines up, can use the original screws that came with the mige.

Cable outlet is designed for the Simtronix supplied connector.

Its an 11hour print, in PLA. I am using silver because I have a lot of it, with 20% infill and 0.2mm print density its about 40 meters of product.

If you request Print a thing or other services to print the stl file its around $40.00 cost plus shipping.

If you want me to print it for you, I will do it for $30 and ship it, if you have your own printer, I will send you the STL file.

I can’t upload the video, but it just slips over the encoder and screws in.

I would love a cover. Would prefer if you can print it. Let me know where to send the money. PayPal?

Sounds like a good job for the Megaprinter in our University hobby club:

With its 0.8mm nozzle and 0.5mm layer height, the prints are a little rough, but manageable. Those in Finland who are interested, please contact me or write to this thread.

0.8 may be a bit rough… PM me email I will send you the STL

Hi Drizute would love you to print me a cover. I am in Australia. Let me know details for cost and freight and will send to you. Thanks

a number that = about 6 rev/sev

Thanks was still getting an occasional error so upped it to 7 now all good.

Will let you know, heading to China on a Biz trip on Wednesday, if I can get it done by the time I leave (7 day trip), I will take it with and ship it from HKG, should be cheaper?? Let me know address.

A huge thanks of appreciation to @Drizute,

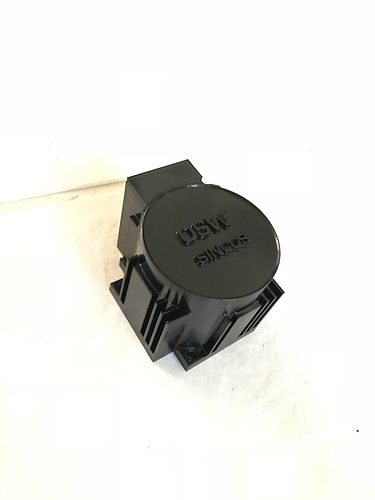

I managed to find a printer via www.3dhubs.com within 4 miles of home here in the UK, picking it up tomorrow and for a reasonable printing cost of £24 using .1mm print density in black, Which I thought was great.

I’ll post a pic once it’s fitted

To speed up fitting check my fitting instructions, you may have to release your encoder to rotate it a bit.

Top work, Drizute, thank you for making this available to the community. I know how much time it takes to make accurate measurements and translate it into SolidWorks or CAD.

Would you mind sending the STL to me as well, please?

Cheers,

Beano

Love the praise and thanks, appreciate it, it however was not that big a deal, todays cad programs make it fairly easy, getting the hole for the cable right took a little trial and error, the rest was easy.

Only took a day to turn around, thanks @Drizute

The fitting was quite tight, especially around the connector almost if the hole could do with being moved slightly closer to the motor housing, but a gentle file around the one side helped open it up to fit.

On my print there were some imperfections on the inside where the cover sits in the outside spacer ring and these imperfections protruded outwards and it needed a good sanding down on the inside to get it to pop on, (it’s very snug) but in the end we got there

I’m thinking about getting a can of black enamel paint on it at a later date too.

Hi.

I installed the simtronix sincos encoder in a small mige with ioni pro HC and simucube and I had an error like Drizute. I have raised the FEV value to 6 rev / s and the fault speed has been corrected.

My question is … how does the value of FEV affect driving ?, that is, should I look for a lower value possible without errors or is that okay?

Thank you.

Use google translator … apologies.

It is just a limit that will give an overvelocity error if wheel is rotating faster than the speed. In simulator usage, it doesn’t really need to be set to anything exactly.

For other use cases for the IONI servo drive, it can be useful to set absolute speed limits for mechanical axises, etc. Remember that IONI is a general purpose, versatile device.

Can’t speak for the other prints, mine fit snug and right first time. There is slag on all prints, that needs to cleaned off, mine is a .2 with a .4mm tip. Remember also the lock collar on the encoder can be set at different levels, a small push on the encoder would eliminate the offset on the hole I think.