Happy days. When GD says a revolution is coming, then one is coming

I’m interested in a wheel platform that support power and data directly to the wheel without any dangling USB cables.

I like collecting steering wheels, but I stopped buying new ones over 12 months ago because I want LCD displays and lit-up buttons any maybe other innovations without a USB cable, and I scratch my head that low-cost DDs like Moza can do it, but Simucube as the premier DD platform cannot.

I like Simucube and I want to stay put, however if there is no Simucube based solution forthcoming, then when another platform can deliver similar fidelity plus supports power / data to the wheel, and high end 3rd party wheel manufacturers like Grid Engineering and Simcore provide support, then I’ll be moving to that eco-system.

Yea that is one of the things with the induction transfer is that it is very inefficient… it is not uncommon to need that 9-12V to get a running 5V… If I remember correctly with my research is that if you go higher voltage you can increase the distance… The issue is getting enough Amperage out of the receiving coil to be able to run everything you want… Full Screens Might take a larger coil than can be retrofit which could be the reason why Moza is using the around shaft generation which is actually, technically, probably more of a motor generator. Fanatec probably is running 24V through the coil but I haven’t really opened it up to see…

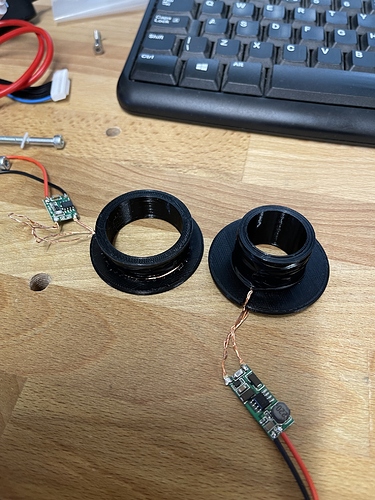

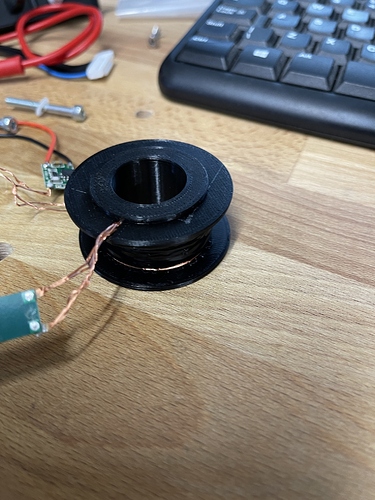

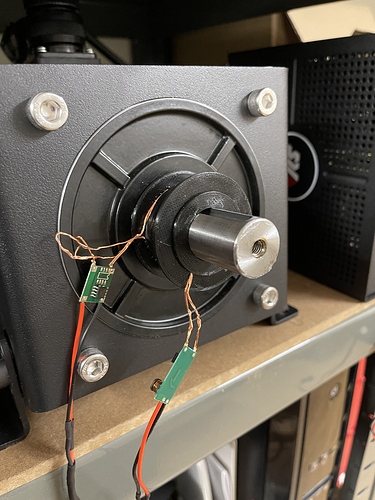

A few photos of my second trial.

For this, I had to unwind the flat coils and hand wind them over shaft mount 3D print.

So, very rough as my coiling is not good at all.

However with 10v input it was rock solid.

Apologise that it’s on a VRS - thats just what I had setup.

Wheel with disply and BLE connection to wheel were perfect.

Coil gets a little warm though

That is very close to what I thought of in drawing, I also had thought of a flatter plate on plate design as well bt I never got to the prototyping stages… I was actually researching more of the actually electronic principles as far as the coil windings and things and got distracted with existing projects :-)… This will be revisited though as it does tie in with things that I want to produce in the future. I did get wireless working well in prototype for our wheels but I definitely don’t like the BatteryPower solution which is why this was the direction… so those two things sort of go hand in hand… the good thing about this sort of set-up and “wireless” is that in reality you can make a wheel with the option or wired or wireless with an adaptor like this at the same time… For very little difference in the overall cost.

On topic: I would appreciate such a solution for being able to use wheels with a higher power demand, e. g. for displays or rumble motors.

I HATE dangling cables, never get rid of the fear of that cable ripping my electronics into pieces if the wheel spins out of control.

On/off topic, power sources at the wheel itself: NO fixed installations. We all know that batteries die sooner or later, lose their capicity, don’t like often recharging, don’t like getting hot, and so on. Fixed battery means trashing the device if the battery fails - a solid reason against spending money for such a device.

Use standard LiIon batteries like 18650, 16340, etc. behind a battery door. Problem solved.

Also solves the shipping problem Mika mentioned earlier.

We are thinking about that, yes. The problem is the quite large technology development task, and what if we decide not to make a wheel of our own with a display - then the development would have been largely for nothing.

We agree. A battery should be able to be changed. Definitiveily not like it is in most of the smartphones these days.